Diamond wire sawing

Context:

Wafering (Fig. 1) is the process by which a silicon ingot is made into wafers in the photovoltaic industry.

A single diamond-coated wire (Fig. 2) is supplied by a spool, wound several hundred times around wire guide rollers, and picked up on the other side by another spool. The wire runs a few hundred meters back and forth in such way that a few meters of new wire is added in one direction for each cycle.

Fig. 1

Fig. 2

Problem

Since the industrial wafering process is done reversing the cutting direction (pilgrim-mode), correlating the non-constant wire speed to the generated wafer surface can be not reliable and very difficult to be performed. Moreover, as thousands meters of wire are used in one multi-wire cut, investigations on tool wear are difficult and usually done by sampling.

Proposed solution

To address the difficulties encountered when investigating the diamond wire sawing using reciprocating machines, an endless wire saw test rig has been designed and built. See how it was designed in PROJECT 01.

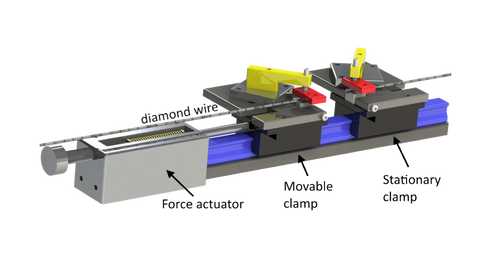

The test rig makes use of industrial diamond wires that are butt-welded in a looped shape by a novel upset welding device. See how it was designed in PROJECT 02.

Project | 01 Endless Wire Saw

Based on the difficulties found in the reversing diamond wire sawing, an endless wire saw test rig that works with a short segment of diamond wire and constant cutting speed has been designed and built. The test rig is based on aerostatic bearing technology for its slides and guides. Unlike industrial reciprocating machines, it can reach high cutting speeds.

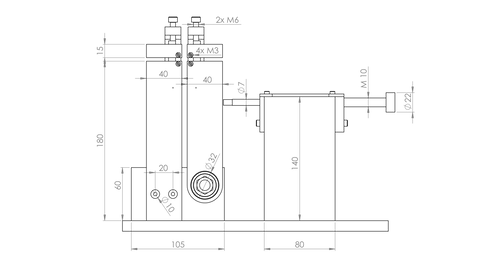

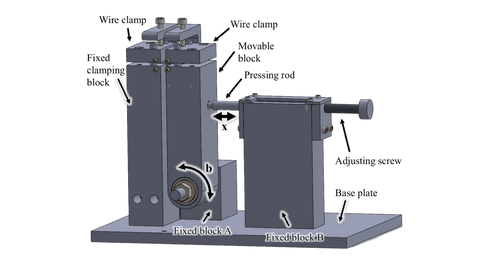

Project | 02 Upset Welding Device

In this device, the wire ends are clamped with tight alignment. By the application of electric current through the wire ends interface, heat is generated by Joule effect and the incandescent heated material is pressed together with controlled force, creating the joint.

As the diamond wire sawing was a new research field at the Laboratory of Precision Engineering, there was no budget available to buy components for new test rigs. Therefore, the design of the new test rigs had to be done based on reconfiguration of machines and parts that could be easily manufactured at the laboratory facilities.